PE vs PET Protective Film, which is better?

When it comes to protecting surfaces from scratches, abrasions, and other potential damage, the choice of protective film is crucial. Two popular options in the market are Polyethylene (PE) and Polyethylene Terephthalate (PET) protective films. In this article, we will delve into the characteristics of both and help you determine which one might be the better choice for your specific requirements.

Polyethylene (PE) Protective Film: A Closer Look

PE protective films are widely used for their versatility and cost-effectiveness. Made from a thermoplastic polymer, PE films offer excellent moisture resistance, making them suitable for various applications, including packaging and surface protection. They are known for being easy to apply and remove, providing a temporary barrier against scratches and dust.

Advantages of PE Protective Film

Affordability: PE films are generally more budget-friendly than some alternatives, making them an attractive option for cost-conscious consumers.

Flexibility: PE films conform well to irregular surfaces, ensuring thorough protection across diverse shapes and contours.

Ease of Application: The adhesive properties of PE films make them easy to apply without the need for specialized equipment.

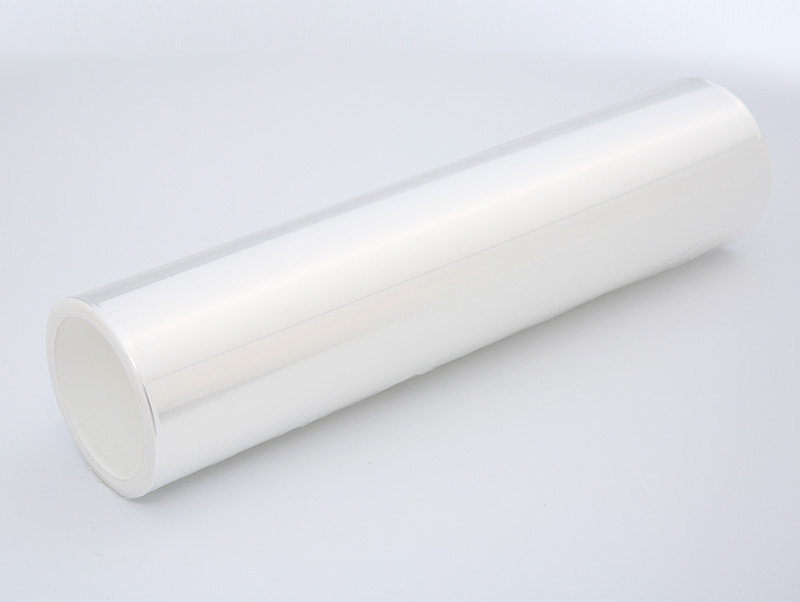

Polyethylene Terephthalate (PET) Protective Film: A Comprehensive Overview

PET protective film on the other hand, are engineered from Polyethylene Terephthalate, a high-performance thermoplastic. These films are recognized for their superior clarity and resistance to chemicals, making them suitable for applications where optical transparency is crucial.

Advantages of PET Protective Film

Clarity: PET films offer exceptional optical clarity, making them ideal for surfaces where maintaining visibility is essential.

Recommended article:10 Questions You Should to Know about how rubber made

The 4 Most Common Rubber Manufacturing Processes

Applications of High Tack Self Adhesive Vinyl

Chemical Resistance: PET films are resistant to many chemicals, ensuring that they can protect surfaces in environments with exposure to various substances.

Durability: PET films are known for their durability and ability to withstand harsh conditions, providing long-lasting protection.

Choosing the Right Protective Film for Your Needs

The decision between PE and PET protective film ultimately depends on the specific requirements of your application. If you prioritize affordability, flexibility, and ease of application, PE protective films may be the better option. However, if you need superior clarity, chemical resistance, and durability, PET protective films might be the ideal choice.

Consider the nature of the surface you are protecting, the environmental conditions it will be exposed to, and your budget constraints when making the decision. Both PE and PET films have their strengths, and the right choice will depend on finding the balance that aligns with your unique needs.

Conclusion: Making the Informed Choice

In conclusion, the choice between PE and PET protective films depends on your specific preferences and requirements. Whether you opt for the cost-effective and versatile nature of PE or the optical clarity and durability of PET, you can find a solution that meets your needs.

For further assistance in choosing the right protective film for your application, please feel free to contact NB Technology. As a trusted supplier in the industry, we are committed to providing expert guidance and quality products to ensure the protection of your valuable surfaces.