Different Types of Pipe Fittings in Plumbing System

The role of pipe fittings in a plumbing system is to connect multiple pipes of the same size or different sizes to change direction, change size, and branch connections. Different pipe fittings play different roles according to shape or process requirements. They are made of different materials, common ones are copper, iron, brass, PVC, etc. There are many types of fittings used in plumbing systems, depending on their purpose and function.

Elbow

Elbows are used to change the direction of pipes. According to the angle, there are usually 45 degrees and 90 degrees; there are also bends and U-shaped return bend. If two pipes of the same diameter are connected, an equal elbow can be used, otherwise, a reducing elbow can be used. Elbow fittings are generally threaded, with internal threads, or internal and external threads. There are also grooved pipe fittings without threads, which generally have 11.25 degrees, 22.5 degrees, 45 degrees, and 90 degrees, and can be connected by groove couplings. Carbon steel elbow fittings can be connected by welding.

90 degree elbow

90 degree elbow, reducing

45 degree elbow

Bend 90 degree, female

return bend

grooved elbow 90 degree

Tee

The tee fitting is T-shaped with three outlets. The two pipes connected by it are perpendicular at 90 degrees. It can make a pipeline branch flow out from two outlets, or it can combine two inlet branch flows into one. According to the diameter of its three ports, it is divided into the equal tee and reducing tee.

Equal tee

reducing tee

grooved reducing tee

Cross

A cross is a pipe fitting with four openings, connecting four pipes at right angles in twos. Because it is in the center of the four connection points, it experiences more stress. From this point of view, the raw materials of cross need to be of high quality, and the processing process needs to be very strict. Cross are commonly used in firefighting systems.

Cross

Coupling

Coupling is a common pipe fitting that connects two pipes, and there are several types of equal, reducing and F&M. Precision threads ensure it won't leak. Couplings made of plastic are provided with gaskets or rubber seals on both sides to prevent leakage.

Industrial Paint vs. Decorative Paint: A Comparative Analysis

Is melamine plywood suitable for outdoor applications?

What are the advantages of living in an expandable container home?

Can an expandable home office be customized?

Installation Guide for Galvanized Corrugated Steel Plate: Tips and Techniques

Advantages of Using Cement Blanket

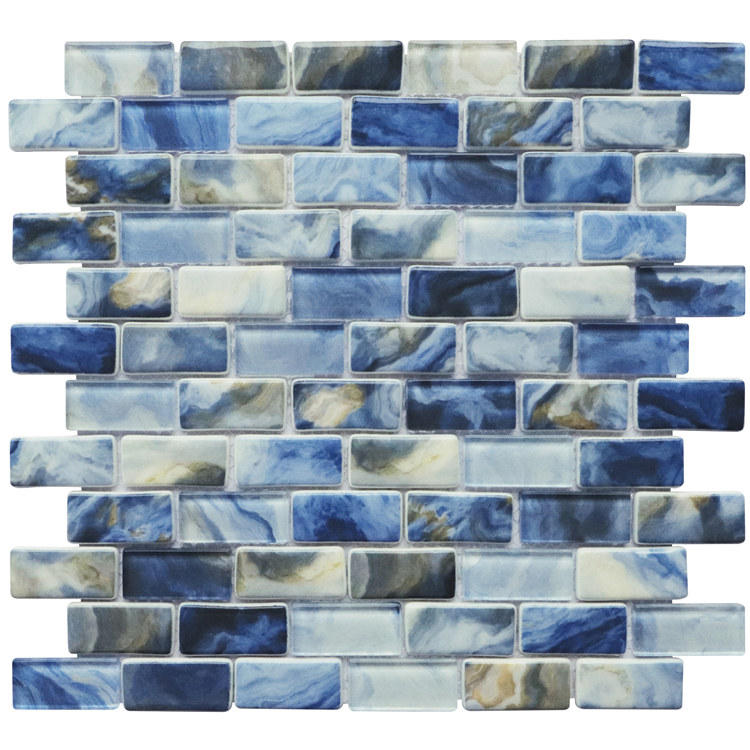

Dive into Elegance: 8 Best Swimming Pool Mosaic Ideas

malleable iron coupling

malleable iron reducing coupling

PVC coupling

Union

The function of the union is similar to the coupling, the difference is that the union is composed of three parts: the nut, the external thread and the internal thread. When needed, the central nut can be turned to remove the fitting without disturbing the rest of the pipe.

union

Nipple

The nipple is externally threaded and is used to connect two pipes. The length of the Nipple is determined by the length of the thread. The center of the Nipple has a hexagonal cross-section to facilitate the wrench to turn it. There is also a Nipple that is a small piece of pipe with no section in the middle, which is usually made of carbon steel.

Malleable iron nipple

carbon steel nipple

Plug and Cap

They are often used to temporarily restrict the flow of the plumbing system, which is necessary during inspection and repair work on piping systems. The plug is internally threaded and the cap is externally threaded.

Plug

cap

All the pipe fittings described above are mainly made of malleable iron. The pipe fittings adopt advanced production equipment and technology. Jianzhi Group has been focusing on making malleable steel pipe fittings for 40 years. Using KTH330-08 malleable cast iron, the tensile strength of our products is 10% higher than the national standard, and the elongation is 33% higher than the national standard. This means that our quality is absolutely trustworthy.

Their enduring popularity is due to the long service life of 60 to 80 years, and the high strength of the material. By choosing high-quality fittings, you will avoid many following troubles.

What is the purpose of dams and their role in water management?

Scaffolding Cross Braces: Enhancing Structural Stability and Safety

Which industries commonly use GFS tanks, and what are the benefits of using them for storage purposes?

HDPE Pipe Floats: The Ultimate Guide to Buoyancy Solutions

Studded T Post: The Versatile Solution for Secure Fencing

Steel Warehouse Buildings: A Comprehensive Guide to Optimize Your Investment

How does the Geotube technology work to contain and stabilize soil and other materials?