CAN YOU CUT PRESTRESSED CONCRETE LINTELS?

Prestressed concrete lintels are incredibly strong because they are made by casting the concrete around high tensile stretched wires that are anchored into the concrete.

The concrete is compressed by the stress in the wires. This makes it very strong so that it can overcome heavy loads, heavy stress, and lasts longer compared to regular concrete.

You basically have added protection around the concrete so that any stress or heavy load is taken on by the wires before it gets to the concrete.

The reasons for prestressed concrete lintels being so durable and practical are also the reasons why it is hard to cut.

However, they can be cut, preferably by concrete cutting professionals using the right tools and equipment.

Cutting or minor trimmings at the ends are okay and should not cause any problems but cutting near the centre can affect the lintel’s load capacity.

It is important to consult a structural engineer before any cutting is done. Before we go further, we have to consider the following:

Are you cutting prestressed concrete lintels that are already installed and part of your building, say a wall or flooring?

Are you cutting uninstalled prestressed concrete lintel pieces?

The answer to these questions means varying methods of cutting. However, whether the concrete lintels are installed or not, we highly recommend you hire professionals to do the work and not do it yourself.

Can You Cut Prestressed Concrete Lintels diamond blades

FACTORS TO CONSIDER WHEN CUTTING PRESTRESSED CONCRETE LINTELS

Type of concrete and reinforcing materials used

The design of the lintel

Intended purpose and other factors

WHAT YOU WILL NEED:

A high-speed concrete saw with a diamond cutting disc or blade

A 9-inch grinder

A cutting or work table

Clamps and vices

Markers

Rulers or measuring tools

PPE like a face mask, goggles, gloves, etc.

A high-speed diamond cutting disc must only be operated by a professional who has proper training, experience in handling concrete saws and knows how to operate the equipment, and is fully aware of the health and safety requirements.

It is highly recommended to consult a structural engineer on how to cut, where to cut, and other important details to keep the structural integrity of concrete lintel.

HOW TO CUT:

Step1 – Scour the Line Where You Will Cut

Use the 9-inch grinder to scour the line where you will make the cut. You will need to clean the metal so you can make a clear mark before you can cut the concrete lintel.

Step 2 -Measure and Mark

Based on the advice of your engineer, measure and make clear marks so you can make accurate cuts.

Step 3 – Make the Cut

Position the blade and start cutting. Make sure you have your goggles and other personal protection equipment on. Keep wiring organised and keep all other clutter to a minimum.

IMPORTANT TIP:

When cutting concrete, wet cutting is always recommended. It is safer for the diamond blade and for the person operating it.

Wet cutting keeps dust to a minimum and stops it from becoming airborne and getting inhaled. Concrete dust particles have crystalline silica that can cause permanent and irreversible damage to the lungs.

Prestressed concrete lintels are incredibly strong because they are made by casting the concrete around high tensile stretched wires that are anchored into the concrete.

The concrete is compressed by the stress in the wires. This makes it very strong so that it can overcome heavy loads, heavy stress, and lasts longer compared to regular concrete.

Explore more:Construction & Real Estate

Exploring the Advantages of Framing Membrane Structures

Railway Continuous Beam Bridge Bearings: Ensuring Stability and Safety

Industrial Paint vs. Decorative Paint: A Comparative Analysis

Is melamine plywood suitable for outdoor applications?

What are the advantages of living in an expandable container home?

Can an expandable home office be customized?

You basically have added protection around the concrete so that any stress or heavy load is taken on by the wires before it gets to the concrete.

The reasons for prestressed concrete lintels being so durable and practical are also the reasons why it is hard to cut.

However, they can be cut, preferably by concrete cutting professionals using the right tools and equipment.

Cutting or minor trimmings at the ends are okay and should not cause any problems but cutting near the centre can affect the lintel’s load capacity.

It is important to consult a structural engineer before any cutting is done. Before we go further, we have to consider the following:

Are you cutting prestressed concrete lintels that are already installed and part of your building, say a wall or flooring?

Are you cutting uninstalled prestressed concrete lintel pieces?

The answer to these questions means varying methods of cutting. However, whether the concrete lintels are installed or not, we highly recommend you hire professionals to do the work and not do it yourself.

Can You Cut Prestressed Concrete Lintels diamond blades

FACTORS TO CONSIDER WHEN CUTTING PRESTRESSED CONCRETE LINTELS

Type of concrete and reinforcing materials used

The design of the lintel

Intended purpose and other factors

WHAT YOU WILL NEED:

A high-speed concrete saw with a diamond cutting disc or blade

A 9-inch grinder

A cutting or work table

Clamps and vices

Markers

Rulers or measuring tools

PPE like a face mask, goggles, gloves, etc.

A high-speed diamond cutting disc must only be operated by a professional who has proper training, experience in handling concrete saws and knows how to operate the equipment, and is fully aware of the health and safety requirements.

It is highly recommended to consult a structural engineer on how to cut, where to cut, and other important details to keep the structural integrity of concrete lintel.

HOW TO CUT:

Step1 – Scour the Line Where You Will Cut

Use the 9-inch grinder to scour the line where you will make the cut. You will need to clean the metal so you can make a clear mark before you can cut the concrete lintel.

Step 2 -Measure and Mark

Based on the advice of your engineer, measure and make clear marks so you can make accurate cuts.

Step 3 – Make the Cut

Position the blade and start cutting. Make sure you have your goggles and other personal protection equipment on. Keep wiring organised and keep all other clutter to a minimum.

IMPORTANT TIP:

When cutting concrete, wet cutting is always recommended. It is safer for the diamond blade and for the person operating it.

Wet cutting keeps dust to a minimum and stops it from becoming airborne and getting inhaled. Concrete dust particles have crystalline silica that can cause permanent and irreversible damage to the lungs.

Why risk doing more damage than good by doing it yourself when you can get professionals to do it in a quick and cost-effective way?

MEGA SAW is Melbourne’s concrete cutting and drilling specialist. We deal with all kinds of concrete using top-of-the-line concrete saws and industry-standard equipment and tools.

We have over 20 years of experience and has been the leading expert ever since. Let us help you do the dirty work and we will get it done in lightning speed, quality guaranteed!

We have over 10 fully equipped vans ready to service both major and minor projects.

If you are looking for a specialist pc strand bonded company who uses only the best practices to get the job done right, then please call us at Megasaw on 1300 920 419 or contact us through our website.

Installation Guide for Galvanized Corrugated Steel Plate: Tips and Techniques

Advantages of Using Cement Blanket

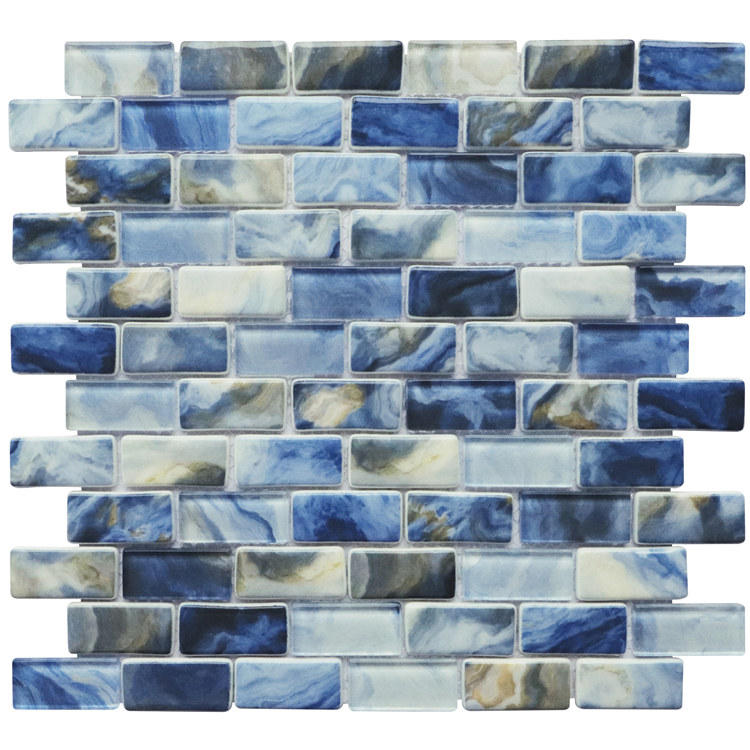

Dive into Elegance: 8 Best Swimming Pool Mosaic Ideas

What is the purpose of dams and their role in water management?

Scaffolding Cross Braces: Enhancing Structural Stability and Safety

Which industries commonly use GFS tanks, and what are the benefits of using them for storage purposes?

HDPE Pipe Floats: The Ultimate Guide to Buoyancy Solutions