The difference between laminated board and ordinary building formwork

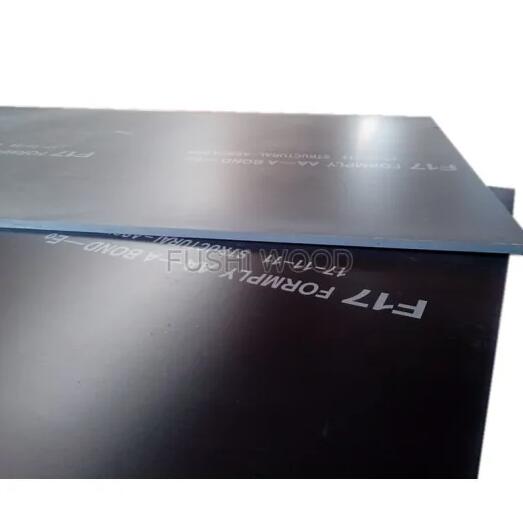

Building formwork is divided into bamboo formwork, wood formwork and steel plate formwork. Laminated building formwork is clear water building formwork. A layer of waterproof film is covered on the laminated building formwork.

There are differences between black film, red film and brown film, and the prices of different laminated building formworks are also different.

Coated paper is impregnated paper (commonly known as coated paper), which is made of special paper impregnated with amino resin (mainly melamine resin) or phenolic resin. After drying to a certain extent, it is cured into impregnated paper and hot pressed on the building formwork.

Building formwork is a temporary structure in the construction process. According to design and manufacturing, there are many types of building formworks, which can be roughly divided into wooden formworks, steel formworks, special-shaped formworks, aluminum formworks, plastic formworks, etc. Among them, wooden formworks can be divided into ordinary formworks and laminated board.

The difference in formwork materials is that the clear water laminated formwork is made of high-quality pine and eucalyptus, and the surface is treated with phenolic resin impregnated paper, which has strong waterproof performance.

Because of its smooth concrete surface, it is called "clear water covered formwork", which is mainly used in high-rise buildings, shear walls, vertical wall panels, dams, tunnels, overpasses, etc.

Arch bridges, beams, columns, etc. are used. When ordinary building formwork is used to cast concrete components, it can only meet the rigidity and flatness specified in the specification. Then the surface also needs to be plastered and decorated, which is mainly used in civil buildings and general industrial buildings.

The cast-in-place concrete components of the film-coated board must not only meet the rigidity (to ensure the cross-sectional size of the component and the deformation after pouring) and flatness specified in the specification, but also meet its flatness.

Under normal circumstances, the surface does not need to be plastered and decorated, and is mainly used in industrial buildings and general industrial buildings.

The main difference between the two lies in the process of making the formwork, whether the concrete surface is plastered, decorated and decorated, and the use requirements of the building.

The above is the difference in materials and use between ordinary building formwork and film-coated board. The price of the same size film-coated board on the market is more than 10 yuan higher than that of ordinary building formwork (red formwork). Why is the film-faced board so expensive?

1. The membrane building formwork is pressed by high temperature and high pressure, with high strength and good toughness. The static bending strength is more than twice the strength of wood.

2. The laminated building formwork has a wide surface and few joints. The board size is 1220×2440mm, 1830*915mm, and the thickness is 12mm, 15mm, 18mm, and 22mm. Compared with the steel formwork, the formwork and demolding speed are fast.

3. The surface of the laminated building formwork is made of imported laminated paper and processed by precision machinery. It has high flatness, is smooth and easy to demold. The concrete surface is flat and smooth, which can cancel the plastering operation and shorten the construction period. It is light in weight, easy to saw and nail, and has good construction performance. It can be made into various special-shaped boards with high construction efficiency. 4. The laminated building formwork has strong water resistance. It is made of phenolic resin by hot pressing and bonding in production. It will not debond after boiling in water for 4 hours, and will not deform when exposed to water during concrete curing.

5. The thermal conductivity of the laminated building formwork is much smaller than that of the steel formwork, which is conducive to winter construction.

6. The turnover of the laminated building formwork is high, which can reach more than 10 times.

7. The laminated building formwork is suitable for horizontal formwork, shear walls, vertical wall panels, viaducts, overpasses, ridges, tunnels and beam-column formwork of high-rise buildings.